AMC Bridge shares highlights of Its 'live' Expert Panel Discussion: Construction Digital Twins

Digitalization is revolutionizing the construction industry, and digital twins are at the forefront of this transformative movement, holding immense promise. Reality capture is crucial to implementing digital twins, and scanning technology forms this process. To explore the potential and functions of scanning in digital twin implementation, AMC Bridge organized an expert panel discussion session.

Expertly moderated by Allan Behrens, Managing Director, Taxal Limited, the discussion focused on using scanning techniques in construction and featured industry experts:

• Steve Combes, Strategic Product Manager, Ericsson.

• Hamzah Shanbari, Director of Innovation, Haskell.

• Matthew Bester, Business Development Manager, BLK Autonomy, Leica Geosystems.

• Corey Johnson, Senior Director, Product Management, Bentley Systems.

• Andy Parnell-Hopkinson, Director, Business Development, UK and Europe, AMC Bridge.

Please visit AMC Bridge Webinars to watch the webinar recording and learn the invaluable insights shared by our panelists on the scanning possibilities and operations in digital twin implementation.

Understanding the panelists’ views on each particular topic is always of great interest. To gain a better understanding of the audience’s perspectives, the webinar started with two polls:

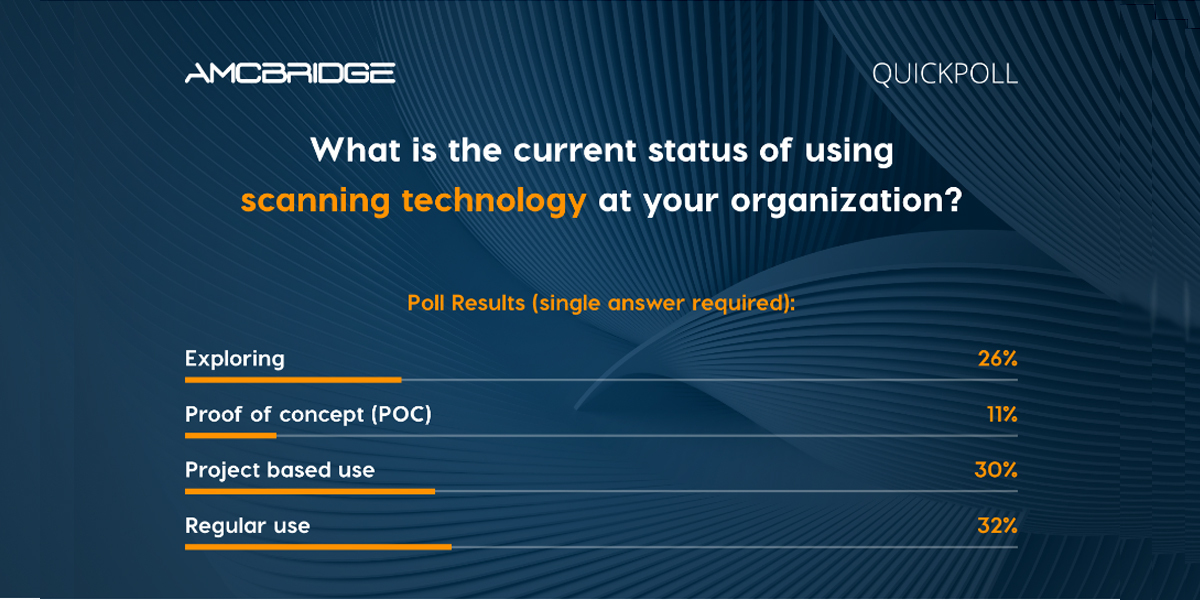

1. What is the current status of using scanning technology at your organization?

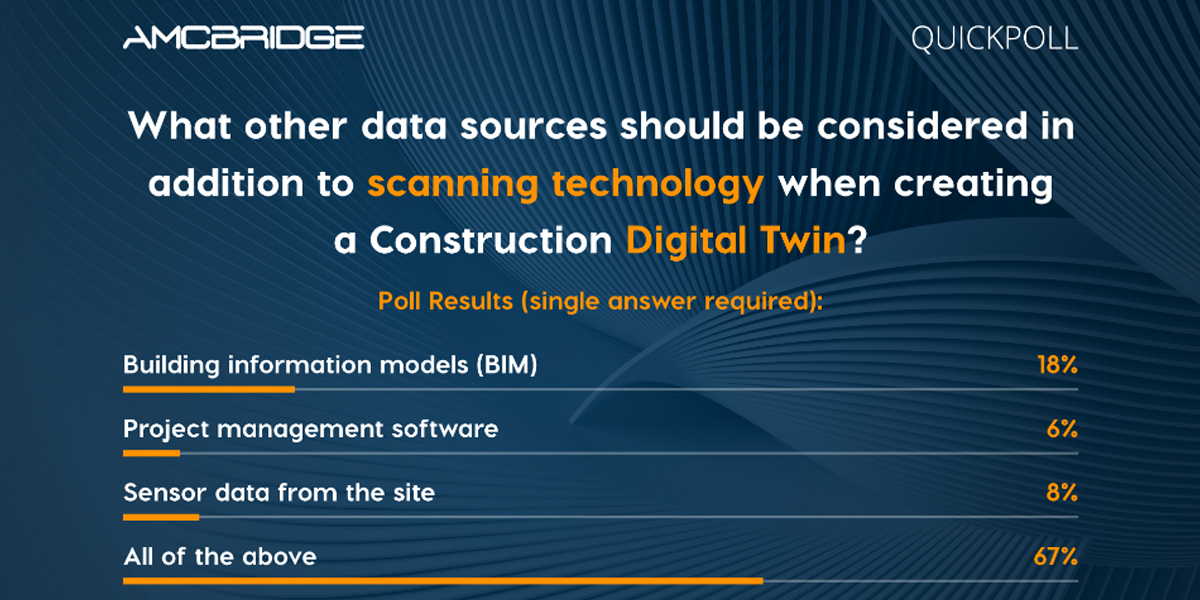

2. What other data sources should be considered in addition to scanning technology when creating a Construction Digital Twin?

The first poll revealed relatively even spread results:

• 32% of respondents regularly use scanning technology in their organizations.

• 30% favor utilizing the technology on a project-by-project basis.

• 26% still explore the possibilities.

• 11% discuss and investigate proof of concepts.

Hamzah Shanbari, Haskell, commented on the first poll’s results: “As one of the largest contractors, we’re constantly using it [scanning technology], but I’m not surprised to see that there’s still a lot of exploration and proof of concepts, especially when we’re talking about the ENR lower half of the Top 400.”

The second poll showed that the majority (67%) consider all data sources important when creating a Construction Digital Twin. BIM takes the second place with 18% of the votes.

The integration of scanning technology has emerged as a crucial aspect of implementing construction digital twins in the ongoing digitalization of the construction industry. The panelists mentioned the following software-related challenges that industry professionals might encounter in harnessing the full potential of scanning technology:

1. Compatibility: different scanning devices may require specific software to process and analyze captured data. Inefficient integration can hinder the smooth data flow and impede the digital twin implementation process.

2. Data processing and management: a vast amount of data generated by scanning technology demands robust software solutions for efficient data cleaning, registration, alignment, and storage. Software tools are needed to handle the data effectively.

3. Integration with other software: scanning technology is often used in conjunction with other software applications, such as Building Information Modeling (BIM) software or project management tools. Ensuring seamless integration between different software systems can be complex and require proper configuration and customization.

The roles of AI and AR in scanning and constructing digital thread

All panelists agreed on the vital role of Artificial Intelligence (AI) and Augmented Reality (AR) in the scanning. These technologies ultimately contribute to creating a comprehensive digital thread by enabling accurate and efficient data capture and analysis. Using AI and AR in construction enhances project planning and management. They empower stakeholders to visualize and analyze project designs, detect potential issues, and make informed decisions.

Matthew Bester, Leica Geosystems, commented on the AI and AR roles in scanning: “What AI will allow us to do is not just to digitize quickly but also to segment, classify, inspect, and basically make some of these processes autonomous, and that’s where it needs to head to. AI would be the actual instigator and starting point for autonomy. It’s absolutely essential.”

Hamzah Shanbari, Haskell, shared how they use AI technologies within their business: “For us, a construction project is changing on a daily basis. When we’re scanning, we are constantly trying to see what was installed, whether it was installed in the right place, and if we are on track. And that’s where the AI component comes in. It automatically identifies specific pipes or ducts and compares that to the model, and says the duct was actually installed 6 inches off of where it was designed to be. The AR piece helps us make sure that people on the job site are visualizing the design correctly.”

The Scan-to-BIM concept and its role in the construction industry

While Scan-to-BIM is not a requirement for all construction projects, it has become an increasingly important, valuable tool for many. This concept is essential to the industry’s digital transformation by improving efficiency, accuracy, and safety in design and construction processes.

“I don’t know if it’s 100% essential because it’s not 100% achievable at this point in time. As we go through the world digitizing things, those things can get added to the BIM catalogs. We can train AI or machine learning to recognize them. It’s not AI for object detection. We can leverage AI algorithms to make use of them. But it’s a long road, and that is the utopian position. To go to a site with a laser scanner or a drone and end up with a full digital twin of your site in BIM without touching the keyboard, it’s something a lot of the people on this panel would like to have, but it’s not there yet. But we’re getting there slowly,” emphasized Steve Combes, Ericsson.

Matthew Bester, Leica Geosystems, shared his vision on the Scan-to-BIM significance: “I think it’s very important. If you look at the value drivers for any capital project, you know it’s going to be saving time and money. If you look throughout the capital asset life cycle, if you follow certain types of guidelines, like ISO 19650 for BIM, you know how to document that process using laser scanning and other mechanisms. It’s absolutely essential to get to a point quickly, cost-effectively, and safely.”

Andy Parnell-Hopkinson, AMC Bridge, mentioned the distinction between the massive amount of data that we get from scanning and what is actually implied by BIM—not just a model. The industry is far away from having AI or other tools that would turn captured scan data into genuinely useful information. “Scanning and BIM are definitely interdependent, but they are not the same thing,” stressed Andy.

Scanning technology accuracy, limitations, and challenges

Scanning technology can capture physical sites and surrounding environments with remarkable accuracy and detail. Laser scanning can measure distances with an accuracy of a few millimeters and capture precise data about surfaces, angles, and dimensions.

However, scanning also has some limitations and challenges. First, it requires a clear line of sight to capture data accurately: obstructions, such as trees, vehicles, and people, may interfere with the scan’s accuracy. Additionally, large amounts of data produced by scanning can be difficult to manage and analyze without the right software tools and expertise. Finally, the cost of scanning technology and the need for specialized operational skills can pose significant challenges for adoption.

“A lot depends on what your outcomes are going to be. Sometimes it’s good to do a quick scan and not have the accuracy there. I don’t think it’s a technology or equipment problem—it’s the people—it’s understanding by the workforce who’s going to process it,” commented Corey Johnson, Bentley, on the accuracy topic.

Steve Combes, Ericsson, added: “Different use cases need entirely different sets of resolutions. Technology is only getting better. The resolution of cameras is getting better. Photogrammetry is well established now. Laser scanning is incredible. The SLAM LIDAR solutions are not as accurate as their photogrammetry techniques in certain circumstances. For example, we are modeling quite difficult things [lattice towers]. They’re very tall and narrow, and most are see-through. We combine different technologies to get a good overall result.”

Best practices

The industry experts identified several key considerations for effectively incorporating scanning technology data into a digital twin:

1. Ensuring data consistency and a clear understanding of the desired outcomes.

2. Recognizing the project’s value and purpose.

3. Understanding the problems the project aims to solve.

4. Determining the degree of digital adoption required for the project.

Scanning technology future

“There’s been a couple of mentions throughout the discussion of the current drawbacks, large data, transferability of the data, and processing time accuracies. I think the future would probably see more mobility, quicker scan and processing times, and more intelligence built into the processing part,” commented Matthew Bester, Leica Geosystems.

The future of scanning technology looks promising, with continued advancements and innovations expected to enhance its capabilities and applications in the construction industry.

The speakers highlighted the factors shaping the future of scanning technology:

• Integration with other technologies: combining scanning with other technologies, like AI, ML, and VR, can enable more efficient data analysis and visualization.

• Improved portability: portable and handheld scanning devices are becoming more widely available and accessible, making scanning more versatile and useful in a wider range of construction projects.

• Real-time data capture and processing: advancements in scanning technology may enable stakeholders to make informed decisions and adjustments on the spot through real-time data capture and processing.

Summary

The valuable insights shared by the panelists can be summarized as follows:

1. Scanning is widely used across the industry, and adoption is growing—from aerial scans to handheld mobile scanners, from LIDAR to photogrammetry, and their combinations.

2. Scanning technology is improving fast and becoming increasingly affordable. However, not all scanning equipment may or should always be used. For example, different countries and locations have restrictions on flying drones. There is an art to knowing the right tool for the job.

3. Data processing and management are major challenges with no simple solution. Even versioning, storing, and viewing a massive amount of data produced by scanning remains a problem.

4. Capturing is only the first step in creating a meaningful digital twin. It should be processed and then combined or compared with design models, real-time data, simulation data, etc.

5. While software vendors work on general solutions, multiple gaps remain related to specific use cases and will need bespoke workflows.

We thank all our panelists for their invaluable contributions to the discussion. To keep track of similar webinars, conferences, and meet-ups, please follow our events calendar.

For more information on how AMC Bridge enables architecture, engineering, and construction companies to implement and leverage digital twins, visit our website; in particular, check out the BIM and Digital Twin, Visualization, and Design and Workflow Automation in AECO pages.

About AMC Bridge

AMC Bridge is a global software development consultancy serving engineering, manufacturing, and construction industries. Since 1999, we have enabled digital transformation for our clients by creating custom software solutions that eliminate data silos, connect complex applications, unlock internal innovation, and democratize cutting-edge technologies. AMC Bridge’s software development experts use extensive experience with APIs of the majority of engineering software solutions and platforms, as well as in-depth knowledge of computational geometry, 3D visualization, and other advanced technologies to solve our clients’ critical business needs.

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.

Newsletter